- HOME

- Technologies

- Highlighted Technologies

- [Safety technology] A loopless style for keeping all users safe

[Safety technology]

A loopless style for

keeping all users safe

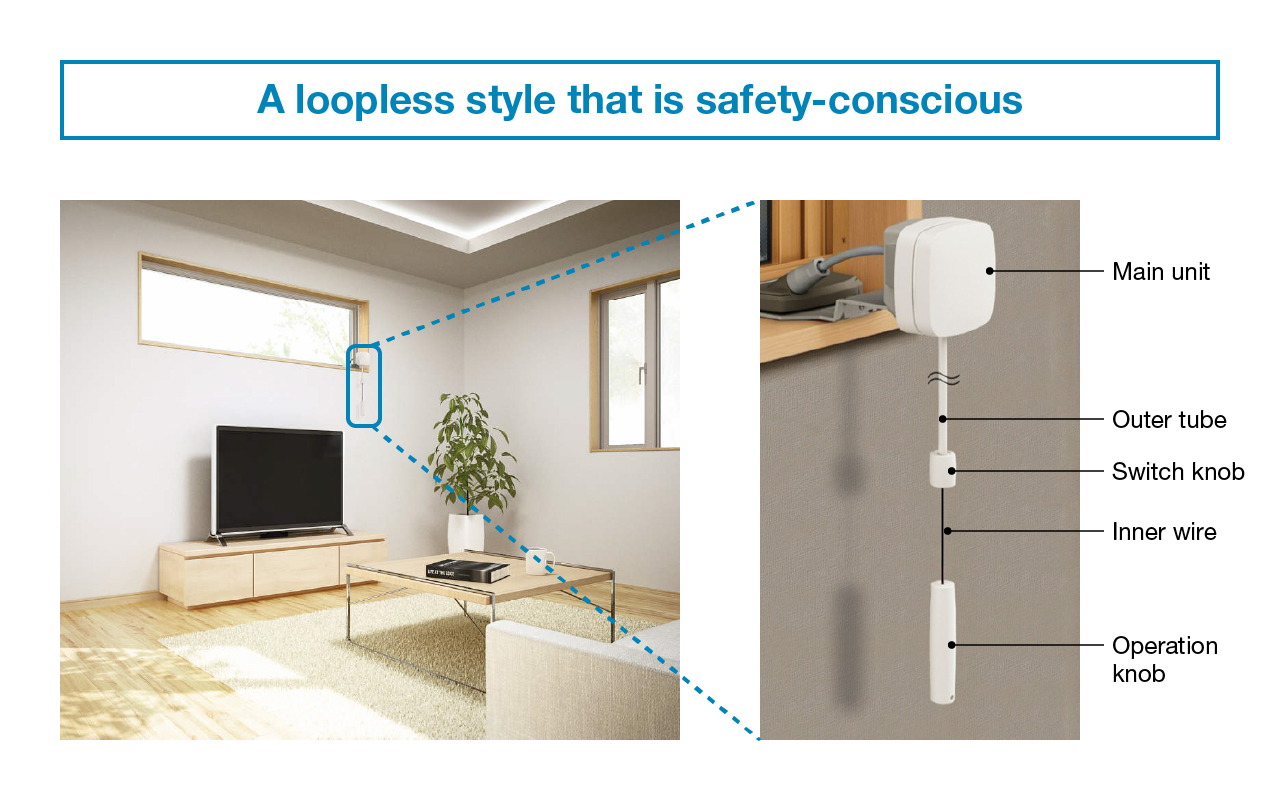

Technologies

The operating components offered by YKK AP for opening/closing windows and insect screens utilize proprietary technology to improve safety. Traditionally, windows installed high out of reach, or roll-up screens which are raised and lowered, had required a loop-shaped operating cord or ball chain to open and close them. The newly introduced technology is a unique opening/closing method called "loopless style," in which all products to be installed are operated by a single cord with no loop, based on a fundamental review of the component structure. This reduces the risk of an accident with a child due to the operating cord, and helps ensure the safety of all users.

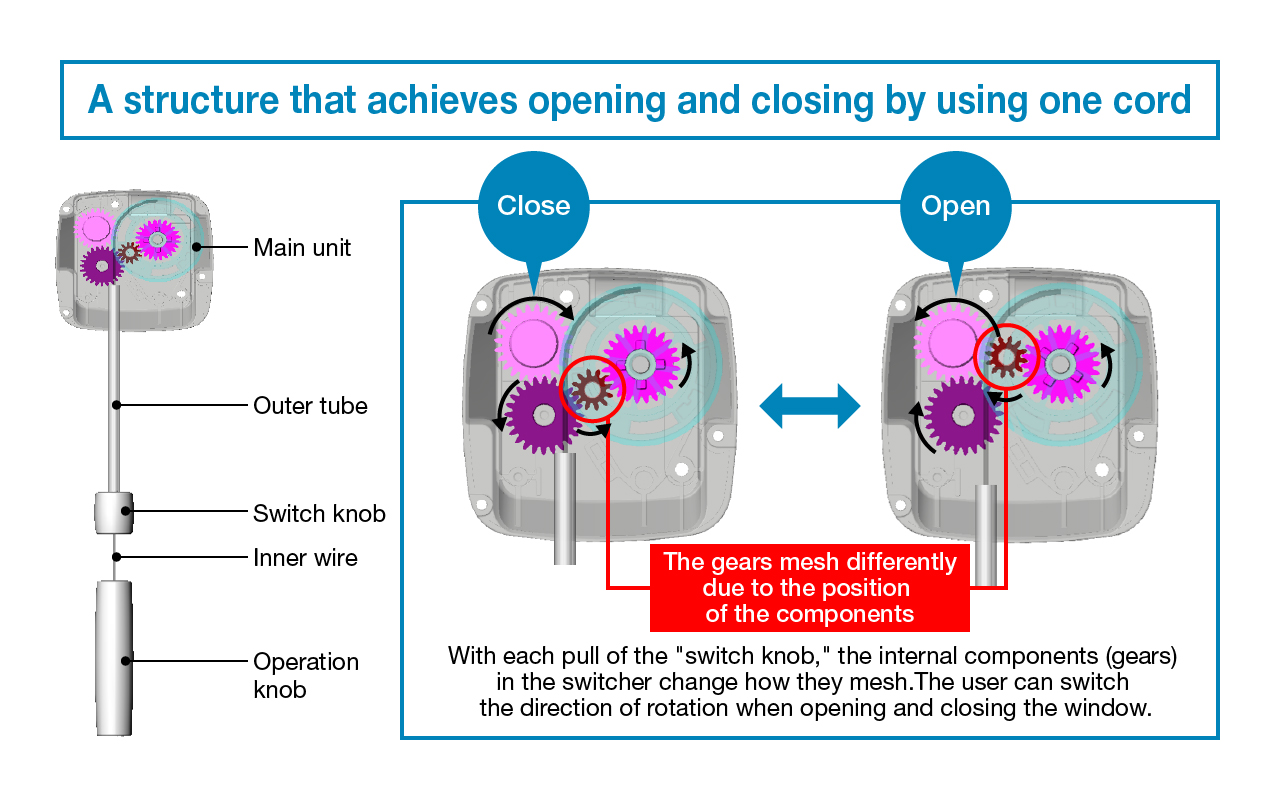

Some may wonder how a window can be opened and closed with only one operating cord. As an operation mechanism, each pull of the "switchover knob" on the operating cord goes through the outer segment to switch how the internal components (gears) in the switcher itself mesh, enabling the user to smoothly switch the direction of rotation when opening and closing the window. This structure allows the user to perform two operations, "open" and "close," by simply pulling a single cord. The design concept of this component technology was inspired by catheters used in the medical field. It employs an industry-first mechanism consisting of an outer segment connected to a switchover knob, together with a wire for opening and closing operations that passes through the inner part of the switcher.

In addition, a safety design has been implemented to prevent accidental operation by children. In the case that a child accidentally pulls hard on the operation cord or hangs from it, the handle of the switchover knob on the operation cord is designed to detach from the cord when a weight of about 200 N (equivalent to about 20 kg) is applied to it. This concept prevents excessive loads from being applied to the operating components themselves, as well as the wire, which prevents components from breaking or falling, and minimizes risks.

Furthermore, during the development stage, we conducted sensitivity evaluations and user verification to pursue operability and ease of use. To ensure that users could operate the product safely and comfortably, we repeatedly built prototypes and made improvements based on analyses of the force required to open and close the product, questionnaire evaluations of how the product felt to operate, and other factors. The development process, based on this user-oriented design concept, has resulted in technology that achieves comfortable operability.