- HOME

- Technologies

- Highlighted Technologies

- Technology for Manufacturing and Supplying Factory-Completed Products with Glass Pre-Installed

Technology for Manufacturing and Supplying Factory-Completed Products with Glass Pre-Installed

TechnologiesA major feature of the APW vinyl window series is that all the windows for an entire house can be delivered directly to the construction site in batches according to the building schedule. To realize this business model, which differs from conventional methods of product manufacture and supply, in which assembly is required after shipment, YKK AP has developed a variety of new proprietary technologies.

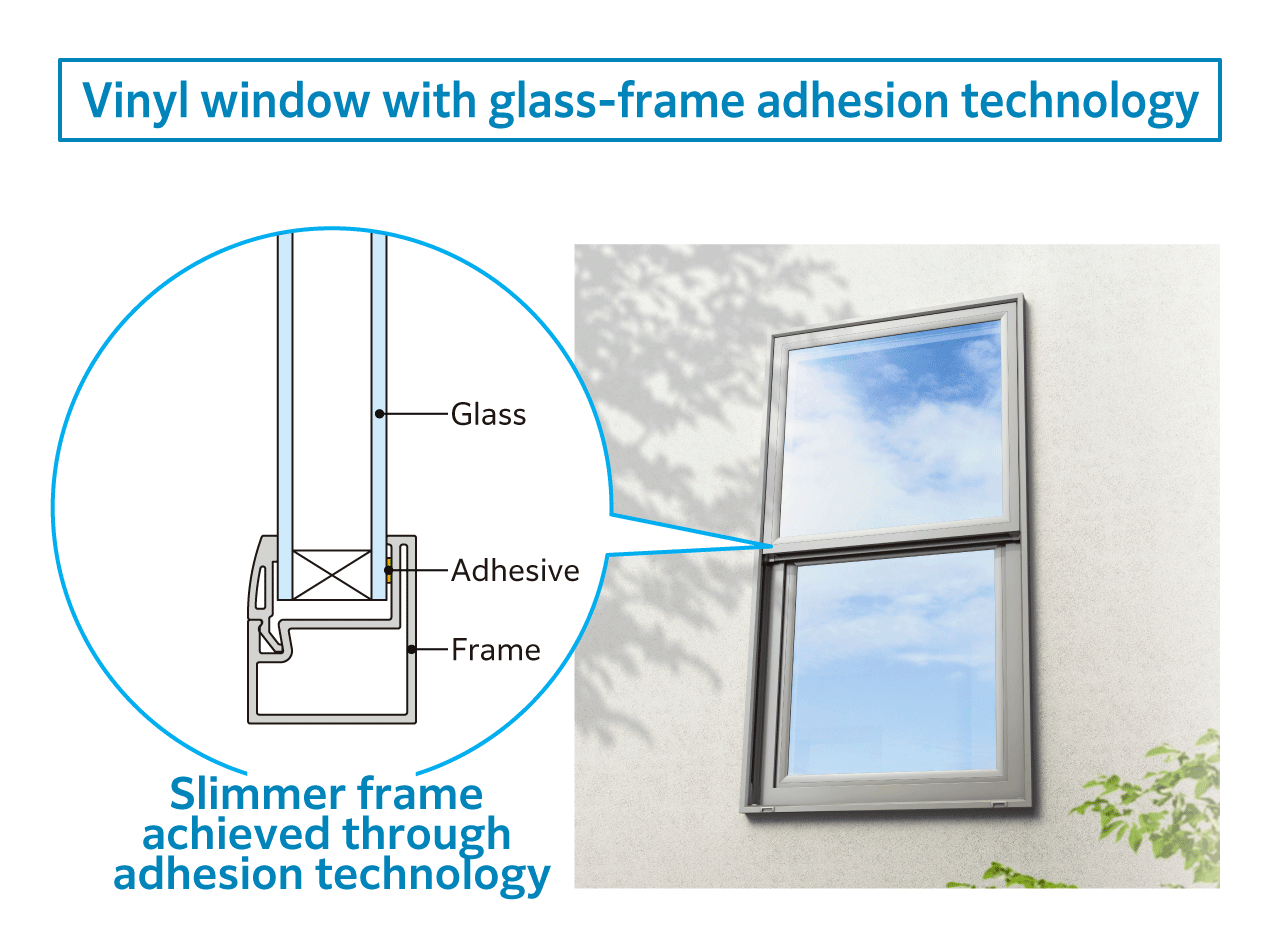

In the past, architectural product manufacturers supplied frames (sashes), glass manufacturers supplied plate glass, and architectural product distributors assembled them into windows, but the APW vinyl window series is shipped as a completed window product with glass installed at the factory. The adhesive-based construction integrates the glass with the frame, resulting in improved frame strength and a slimmer design.

To realize this adhesive-based construction, YKK AP has developed a series of manufacturing technologies, from adhesive application to high-precision alignment of the frame and glass. These include technologies for controlling the rotation speed of a gear pump to match the movement speed of the adhesive application nozzle, and high-precision robot-based positioning technology to accurately mount the glass into the frame. With technologies like these, the Company has achieved automation of the glass adhesion process, regardless of product size or shape, on a "multi-product production line" that manufactures all the windows for a single house on a single production line. This allows production to be performed without the need to change adhesive application equipment (process changeover), resulting in improved productivity and consistent quality.

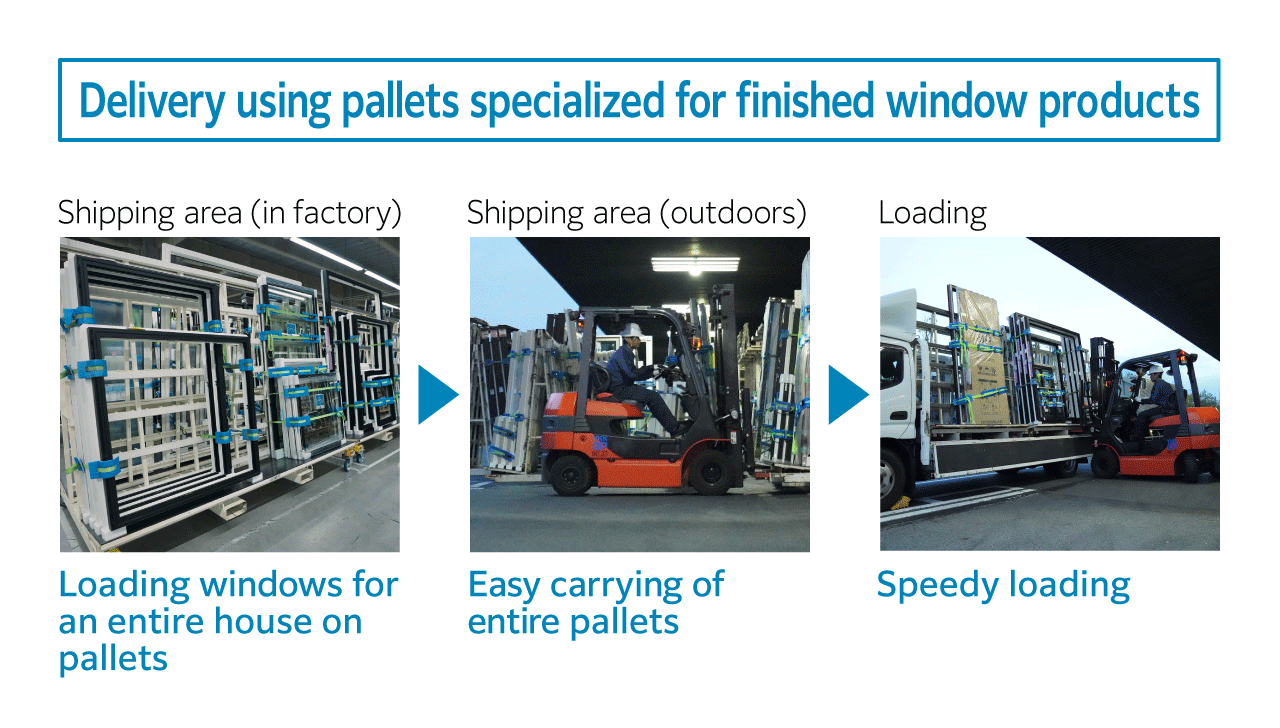

In addition, in order to deliver windows for an entire house, a pallet exclusively for finished window products (window pallet) has been developed. The windows for one house are stacked on pallets in the factory, allowing the pallets to be loaded as is immediately after the delivery truck arrives at the factory.

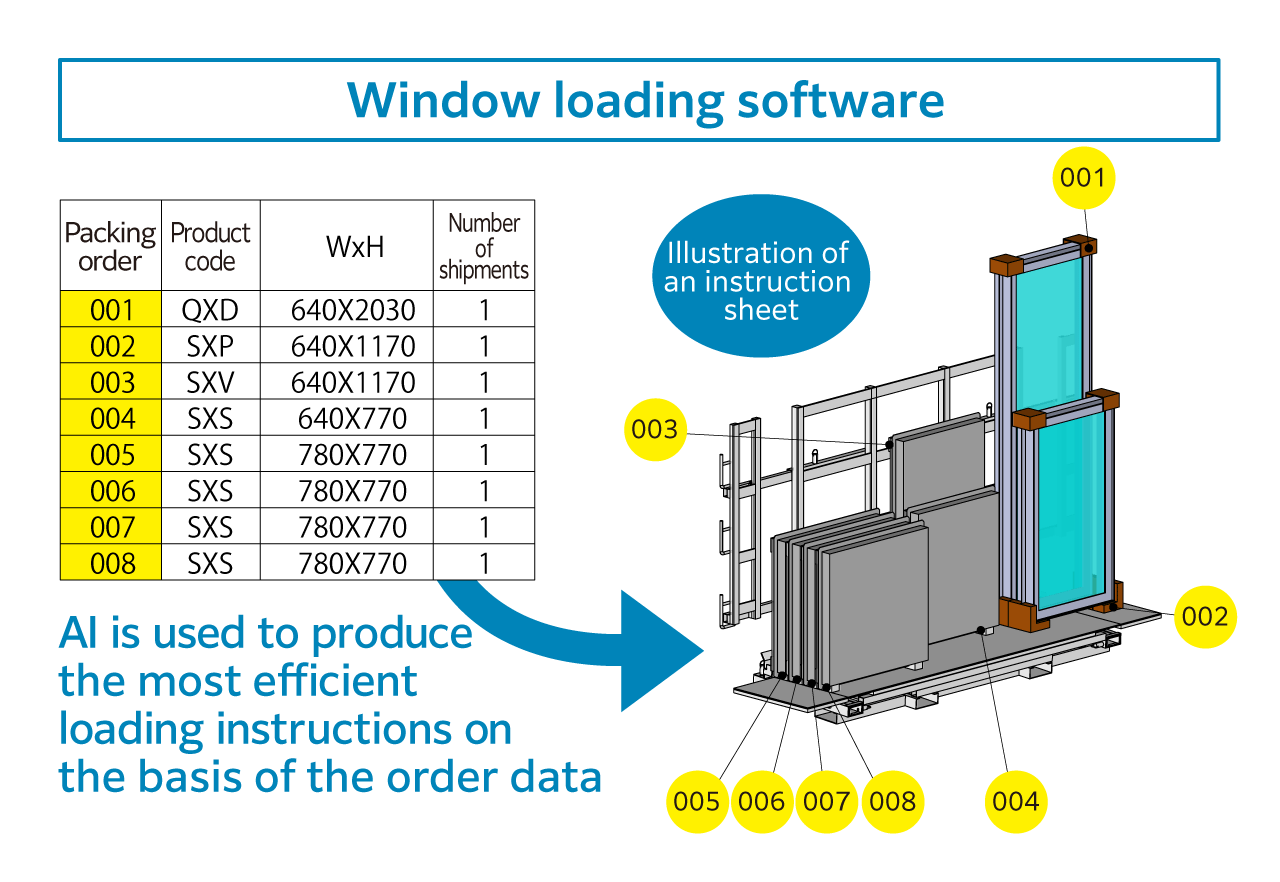

Previously, loading windows onto pallets required experience and skill on the part of the workers, so the challenge was to systemize the process so that anyone could do the work. To this end, YKK AP developed "window loading software" that applies digital twinning (reproduction in virtual space) to create instruction sheets with specific 3D descriptions of how windows should be loaded onto pallets and in what order. This allows anyone to perform optimized loading operations while checking the configuration of the cargo digitally. The number of pallets and trucks required can now be determined at the planning stage, something that was previously reliant on workers’ experience. Trucks can now be dispatched in a systematic manner, without causing waste, which has led to a reduction in the burden on drivers and in CO2 emissions.

Through a series of technological developments such as these, we have realized a new system of delivering windows for an entire house to construction sites with consistent quality.