- HOME

- Technologies

- Highlighted Technologies

- "Preventing Window Leaks"Technology for Maintaining Consistent Waterproofing, Regardless of Installation Skill Level

"Preventing Window Leaks"

Technology for Maintaining Consistent Waterproofing,

Regardless of Installation Skill Level

Technologies

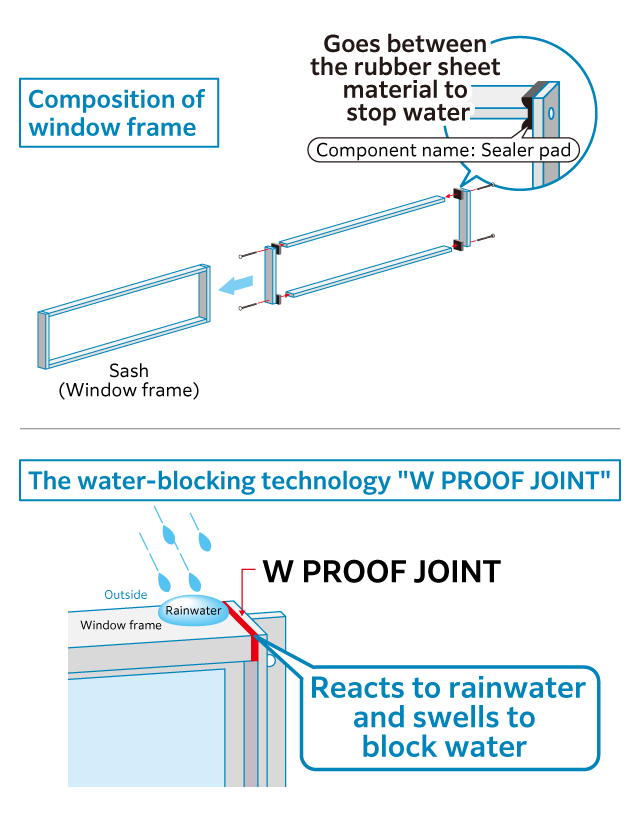

Window frames have four sash components, top, bottom, left, and right. They are assembled using screws with a rubber waterproof sealer pad (*1) sandwiched between each joint to prevent rainwater from entering. Sealar pads are supposed to securely seal gaps between sash components to ensure water tightness, but we faced issues with water leaking through those gaps, caused during haulage after site assembly or insufficient worker installation skill.

YKK AP developed the “W PROOF JOINT”, our own waterproofing technology, and “Screw hole protrusion processing,” to offer window products equipped with consistent watertight performance, regardless of the technician’s skill level during assembly and installation.

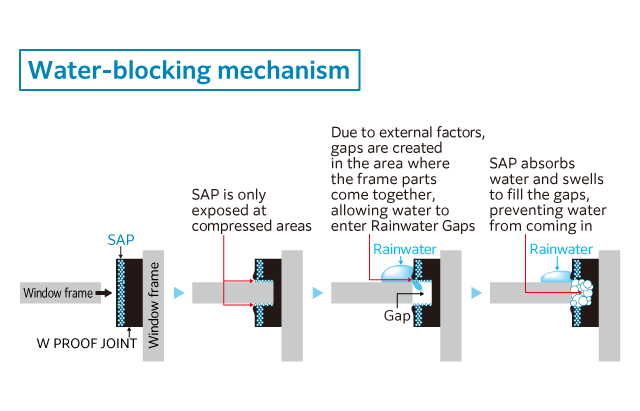

W PROOF JOINT is YKK AP’s own sealer pad, and the surface layer of this sealer pad, which is mainly made of rubber, is kneaded with SAP (Super Absorbent Polymer), a resin material with high water absorbency. Even if a gap forms at the sash joints due to external factors, the SAP will react to rainwater, etc., expanding to prevent water from infiltrating.

Since the SAP is kneaded into the rubber and contained within the sealer pad, it will not absorb water even if some gets on the sealer pad during storage or before assembly. The sealer pad is compressed when the frame’s joints are screwed together, with the rubber changing shape only in the compressed part, exposing the SAP. The exposed SAP reacts to surface water and expands, preventing rainwater from infiltrating and forming a structure that maintains watertight performance over a long period of time. We also adjusted the hardness of the rubber material to further enhance waterproof performance. After approximately three years of experimenting and improvements, we adjusted all key determinants, from the amount and location of the SAP to the hardness of the sealer pad. The completed W PROOF JOINT exhibits optimized reactivity to water.

During evaluation tests we verified the product’s watertight performance under various potential situations, including environments with continuous rainfall, repeated absorption swelling and drying, complex deterioration from water, heat, and ultraviolet rays, and exposure to various chemicals during maintenance.

*1: The component name of the sealer pad may vary from country or region.

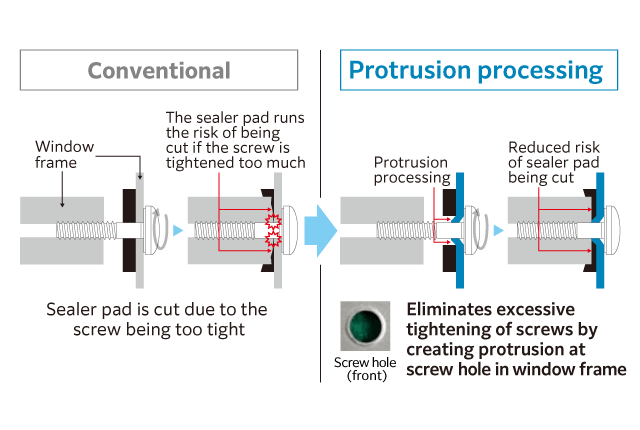

The design uses Protrusion Processing for the window frames to control screw tightening, and prevents the W Stop Joint seal from breaking due to overtightening. Creating a slight overhang around the screw hole prevents physical damage to the sealer pad if the screw is overtightened. The assembly technician can sense when the overhang comes in contact with the transverse component, ensuring appropriate tightening.